Home Up Search Reference Manuals Return

Creates coordinate systems

| x | = | Along the track |

| y | = | To the right, when looking in positive X-direction |

| z | = | Downwards |

| Direction | Greek letter | Gensys abbrv. |

||

| X-rot | = | φ | = | "f" |

| Y-rot | = | χ | = | "k" |

| Z-rot | = | ψ | = | "p" |

lsys e_abs_bendrf esys_1 Vo `Xtrac_start - (10+buff.A_1)` # Create an Euler system

ro_trac_design f_trac_design z_trac_design # The recommendation is to create

4 4 4 4 4 4 # one Euler system per vehicle

lsys l_local lsc_1 esys_1 0. 0. 0. # Create a linear system for the car-body

lsys l_local lsb_11 esys_1 acb_ 0. 0. # Create a linear system for the leading bogie

lsys l_local lsa_111 esys_1 acb_+aba_ 0. 0. # Create a linear system for the first wheelset in leading bogie

lsys l_local lsa_112 esys_1 acb_-aba_ 0. 0. # Create a linear system for the second wheelset in leading bogie

lsys l_local lsb_12 esys_1 -acb_ 0. 0. # Create a linear system for the trailing bogie

lsys l_local lsa_121 esys_1 -acb_+aba_ 0. 0. # Create a linear system for the first wheelset in trailing bogie

lsys l_local lsa_122 esys_1 -acb_-aba_ 0. 0. # Create a linear system for the second wheelset in trailing bogie

Where:

| acb_ | = | Longitudinal distance from mid-point of car-body to mid-point of bogie |

| aba_ | = | Longitudinal distance from mid-point of bogie to wheelset |

Creates masses

Example:

mass m_rigid_6 car_1 lsc_1 0 0 -hccg_ mc_ mc_ mc_ Jfc_ Jkc_ Jpc_ # Create a car-body

mass m_rigid_6 bog_11 lsb_11 0 0 -hbcg_ mb_ mb_ mb_ Jfb_ Jkb_ Jpb_ # Create a bogie frame

mass m_rigid_6 axl_111 lsa_111 0 0 -ro_ ma_ ma_ ma_ Jfa_ Jka_ Jpa_ # Create a wheelset

mass m_rigid_6f trc_111 lsa_111 0 0 0. 0. mt_ mt_ Jft_ 0. 0. # Create a track-piece

. . .

mass m_rigid_36b car_1 lsc_1 a b -h mxx mxy mxz mxf mxk mxp # Defines a mass having

myx myy myz myf myk myp # products of inertia

mzx mzy mzz mzf mzk mzp

mfx mfy mfz mff mfk mfp

mkx mky mkz mkf mkk mkp

mpx mpy mpz mpf mpk mpp

. . .

mass m_flex_1 car_1 fq1 damp1 fq2 damp2 fq3 ,,, # Adding flexible modes to a rigid mass

. . .

Connecting the masses to each other.

Example:

coupl p_lin36 kmbl_=

0. 0. 0. 0. 0. 0.

12e6 0. 0. 0. 0. 0. # Bushing property

0. 8e6 0. 0. 0. 0. # A 6x6 dimensional linear coupling matrix

0. 0. 12e6 0. 0. 0.

0. 0. 0. 10e3 0. 0.

0. 0. 0. 0. 10e3 0.

0. 0. 0. 0. 0. 10e3

coupl k kmbl bog_11 aba_-.3 -1. -.4 # Bushing. The coupling

lnk_11l -.3 -1. -.4

kmbl_ # Property

esys_1 m # Coordinate system and direction of action

coupl k ktr car_1 7.5 0. -0.4 # Traction rod

bog_11 -.2 0. -0.3 # Body #2 and its attachment coordinate

25e6 # Property

esys_1 c # Coordinate system and direction of action

coupl kc czcb car_1 `acb_+0.34` 1.25 -1.0 # Vertical damper

bog_11 0.34 1.25 -0.5 # Body #2 and its attachment coordinate

`2*pi*20.*40e3` 40e3 # Properties. Cut-off frequency at 20[Hz]

esys_1 z # Coordinate system and direction of action

coupl p_nlin_s kycbs_= # Lateral bumpstop property

0. # Pre-stress force

0.030 0. # Break-point #1 [m],[N]

0.040 15e3 # Break-point #2 [m],[N]

0.090 2e6 # Break-point #3 [m],[N]

coupl k kycbs car_1 acb_ 0. -1.0 # Lateral bumpstop. The coupling

bog_11 0. 0. -1.0 # Body #2 and its attachment coordinate

kycbs_ # Property

esys_1 y # Coordinate system and direction of action

coupl k_coil3 kzcb # Compressed coil spring between car-body and bogie

car_1 acb_ 1. -1. # Body #1 and its attachment coordinate

bog_11 0. 1. -0.8 # Body #2 and its attachment coordinate

600e3 600e3 900e3 0. 0. 0. # Stiffnesses in all 6 directions

hfree hcomp rf # Height of spring

esys_1 m # Coordinate system and direction of action

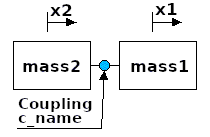

Deformation in a coupling with zero-length

c_name.d= mass2.x - mass1.xThe force in the coupling is defined as:

c_name.F= Stiffness * c_name.dThe forces acting on the two masses are defined as:

c_name.F1x= c_name.F c_name.F2x= -c_name.FSum up the the total force acting on the masses:

mass1.Fx= mass1.Fx + c_name.F1x mass2.Fx= mass2.Fx + c_name.F2xBoth ends of a coupling with a direction of action equal to "x", "y", "z", "f", "k", "p", "m" must coinside. If not, a force will be generated.

Couplings with length

Must have a direction of action equal to "cx", "cy", "cz", "c" or "cu".

Direction "cx" means that the coupling is acting in longitudinal direction,

but the initial longitudinal distance between its two ends are removed from the force calculation:

c_name.F= Stiffness * ( c_name.d - c_name.l )Direction "cy" and "cz" works in the same way as "cx", but they work in lateral and vertical direction.

Couplings with a direction of action equal to c or cu gives forces along the coupling. In these couplings a positive value in variable c_name.d means an elongation of the coupling. Also in these types of couplings the original length of the coupling is removed, when calculating the force in the coupling.

Apply constraints on masses.

Example:

constr fix_free_1 axl_111.k= 0. # Elliminate the pitch rotation in the wheelset constr conn_free_1 abox_111l.x = 1. axl_111.x +1.025 axl_111.p # Force the axlebox to constr conn_free_1 abox_111l.y = 1. axl_111.y # follow the wheelset constr conn_free_1 abox_111l.z = 1. axl_111.z -1.025 axl_111.f # in all directions constr conn_free_1 abox_111l.f = 1. axl_111.f # except pitch constr conn_free_1 abox_111l.p = 1. axl_111.p constr conn_free_1 abox_111l.vx= 1. axl_111.vx +1.025 axl_111.vp # Also apply constraints constr conn_free_1 abox_111l.vy= 1. axl_111.vy # on the velocity constr conn_free_1 abox_111l.vz= 1. axl_111.vz -1.025 axl_111.vf # equations constr conn_free_1 abox_111l.vf= 1. axl_111.vf constr conn_free_1 abox_111l.vp= 1. axl_111.vp

Low level commands.

Example:

func const bo_ = 0.75 # Define a constant

func operp vkmh= 400 - vkmh_deacc * time # Evaluate formulas

func char ctrack_irreg= "Ideal_track" # Define a character variable

Create a conditional if_then-statement.

Example:

if_then lsa_111.pn .gt. Xtrac_stop func print06_char_all " " func print06_char_all " Execution interrupted due to lsa_111.pn > Xtrac_stop" func print06_char_all " ----------------------------------------------------" func stop endif

Create a conditional if_then_init-statement.

Example:

if_then_init .exist. cp3_111r.Fx s_var gpdat_force1 cp3_111r.Fx s_var gpdat_force1 cp3_111r.Fy s_var gpdat_force1 cp3_111r.Fz endif

Create a conditional if_then_init_char-statement.

Example:

if_then_char_init CalcType .eq. TSIM pre_process= 'quasi $CURRENT_FILE' post_process= 'mplot mplotf/Tsim_All_BoBo.mplotf $IDENT' endif

Include the contents from an other file

Example:

insert file $genkpf/ENS1002t32.5_uic60i40.kpfr

Group of commands that are frequently used on each car-body, bogie or wheelset can put in a substruct to made the tsimf-file smaller.

Example:

substruct interrupt_criterions [ # $1 Wheelset number func operp whe_$1l.z= axl_$1.z - bo_ * axl_$1.f # Vert position of left and func operp whe_$1r.z= axl_$1.z + bo_ * axl_$1.f # right wheel func operp wr_$1l.gap= ral_$1l.z + tral$1l.z + 0.028 - whe_$1l.z # Vert difference between wheel and rail func operp wr_$1r.gap= ral_$1r.z + tral$1r.z + 0.028 - whe_$1r.z # (flange height= 28mm) s_var sngl wr_$1l.gap s_var sngl wr_$1r.gap # Save the variable on id-file if_then wr_$1l.gap .gt. 0.10 func print06_char_all " " func print06_char_all " Execution interrupted due to wr_$1l.gap > 0.10" func print06_char_all " ----------------------------------------------" func stop endif if_then wr_$1r.gap .gt. 0.10 func print06_char_all " " func print06_char_all " Execution interrupted due to wr_$1r.gap > 0.10" func print06_char_all " ----------------------------------------------" func stop endif ] in_substruct interrupt_criterions [ 111 ] # $1 Wheelset number in_substruct interrupt_criterions [ 112 ] in_substruct interrupt_criterions [ 121 ] ... etc.

Head lines are defined with commad head:

## ## Headlines ## ================================================================ head 1 "" # Intentionally left blank in order to set the page title in MPLOT head 2 "Railway vehicle with two bogies; 4 driven axles; $CalcType" head 3 "Wheel/Rail= $ckpfr; Friction=$mu_; Speed=$vkmh" head 4 "Curve Radius=$CurveRadius; Track irr.=$ctrack_irreg" # head 5 "Variation: "

Maximum 10 head lines can be defined. Every line is read until end-of-line. Maximum 80 character per line.

GENSYS uses the same input data file for all types of analysis. However a few input data are analysis specific. These analysis specific commands has mainly been collected in the following four commands: fresp_param, modal_param, quasi_param and tsim_param.

Program FRESP calculates frequency response spectras. The following line is only read by program FRESP:

fresp_param= Fourier_CG1 1.e-4 fstart= .3 fstop= 20. fstep= -1.06

The analysis in the program FRESP is linear, Before the calculation starts the model will be linearized. The linearization amplitude is given in the first argument in analysis Fourier_CG1. In the example above the linearization amplitude is set to 1.e-4 which equals 0.1[mm]. The linearization of the model is made automatically.

Before the analysis in program FRESP starts, it is recommended that initial values from program QUASI are calculated first, and the initial values are feed into FRESP via the initval read_gpdat-command. In order to ensure that all forces in the model are in equilibrium.

Command fexcit is also an input data command, but the command must be given after the masses has been defined. Therefore you will find the documentation about "fexcit" later in this manual page.

Program MODAL performs modal analysis, finding all eigenvalues in the input data model. The following line is only read by program MODAL:

modal_param= Schur_fact1 1.e-4

Before the analysis in program MODAL starts, it is recommended that initial values from program QUASI are calculated first, and the initial values are feed into MODAL via the initval read_gpdat-command. In order to ensure that all forces in the model are in equilibrium.

Program QUASI performs quasi statical analysis, searching the position of all integrated variables where all internal forces are balanced with respect to external forces and acceleration fields. The following line is only read by program QUASI:

quasi_param= Damped_Tens 1.e-4 .2 10 16.

QUASI automatically stores the position of the vehicle in the GPdat-file. If the user is interested in storing forces, displacements, etc. on the MPdat-file he or she must specify those variables in command s_var scalar_0.

Program TSIM performs time domain integration. The following line is only read by program TSIM:

tsim_param= heun_u tstart= 0. tstop=10. tstep= 0.001 tout= 0.005

In the input data file the user can specify pre- and post- process commands.

Preprocess commands will be executed before the calculation begins.

Postprocess commands will be executed when the calculation is finished.

## ## Pre- & Post- Processing ## ========================================================== if_then_char_init CalcType .eq. TSIM .or. CalcType .eq. MODAL pre_process= 'sed "s!runf/Master.runf!$CURRENT_FILE!" npickf/flex_car.npickf > npickf/$IDENT.npickf' pre_process= 'npick npickf/$IDENT.npickf' pre_process= 'quasi $CURRENT_FILE' post_process= 'mplot mplotf/Tsim_All_BoBo.mplotf $IDENT' # post_process= 'mplot mplotf/critSpeedGoalfunc.mplotf $IDENT' # post_process= 'mgv diags/$IDENT.ps' endif

Create an input data file for program NPICK with the UNIX sed-command:

pre_process= 'sed "s!runf/Master.runf!$CURRENT_FILE!" npickf/flex_car.npickf > npickf/$IDENT.npickf'

Launch the NPICK program:

pre_process= 'npick npickf/$IDENT.npickf'

$IDENT will be replaced with the name of actual ident

$CURRENT_FILE will be replaced with the name of current input data file

Set the initial values for all equations in the model. This is necessary in the FRESP- and MODAL-program. In program TSIM this is not necessary, but it can avoid initial vibrations.

pre_process= 'quasi $CURRENT_FILE'

After the analysis in the CALC program, the user may wish to calculate max. track-shift forces, max. flange climb ration, different wear index, ride index,,, etc.

post_process= 'mplot mplotf/Tsim_All_BoBo.mplotf $IDENT'

The Designed Track Gauge is defined with the following two variables:

func const bo_ = 0.75 # Lateral semi-distance between the nominal rolling circles of the wheels func const TrackGauge= 1435. # Gauge to be used in the intpl_track_irr-commands

N.B. The track irregularity files contains the absolute gauge. Why it is necessary to use a track file with the correct gauge. Read more about "Track Gauge" under Modify the track gauge

The track alignment is described in two parts:

Designed track geometry and

Track irregularities.

The designed track geometry describes the curve radiuses and cant(superelevation).

Track irregularities are the deviations from the designed track geometry.

Often the Designed track geometry and Track irregularities are separated into two parts.

However there exists track recording vehicles that measures the both signals at the same time,

in this case command

func intpl_track_irr3

shall be used.

Example:

### ### Track irregularities ### ========================================================== func char ctrack_irreg= NoTrackIrr # Output in header lines #[-]{ func const bo_ = 0.75 # Lateral semi-distance between the nominal rolling circles of the wheels func const TrackGauge= 1435. # Gauge to be used in the intpl_track_irr-commands # if_then_char_init ctrack_irreg .eq. "NoTrackIrr" # {{ func const YMtrac= 1e-3 # From mm to m; Scale factor 1.00; Lateral irregularities func const ZMtrac= 1e-3 # From mm to m; Scale factor 1.00; Vertical irregularities func const GMtrac= 1e-3 # From mm to m; Scale factor 1.00; Gauge irregularities func const CMtrac= 1e-3/(2*bo_) # From mm to rad; Scale factor 1.00; Cant irregularities func const XtracStart= 0. func const XtracStop= 30000. func intpl_track_irr2 XtracStart XtracStop Ideal_track TrackGauge # elseif_then_char_init ctrack_irreg .eq. "UIC518_wheel_unloading" # }{ func const YMtrac= 1e-3 # From mm to m; Scale factor 1.00; Lateral irregularities func const ZMtrac= 1e-3 # From mm to m; Scale factor 1.00; Vertical irregularities func const GMtrac= 1e-3 # From mm to m; Scale factor 1.00; Gauge irregularities func const CMtrac= 1e-3/(2*bo_) # From mm to rad; Scale factor 1.00; Cant irregularities func const XtracStart= 0. func const XtracStop= 3000. func const worstPos= 66. func intpl_r lat_trac -100.0 0.0 XtracStop 0.0 func intpl_r vert_trac # vertical alignment in mm -100.0 0.0 -10.0 0.0 -9.0 0.0 -8.0 0.0 0.0 0.0 worstPos-6-.1 0.0 worstPos-6-.00006 0.0 # Several points in order to avoid ringing in the spline interpolation worstPos-6-.00004 0.0 worstPos-6-.00003 0.0 worstPos-6-.00001 0.0 worstPos-6 0.0 worstPos-6+0.0003 0.0005 worstPos-6+0.0006 0.001 worstPos-6+0.006 0.01 worstPos-0.006 9.99 worstPos-0.0006 9.999 worstPos-0.0003 9.9995 worstPos 10.0 # 20 dip on high rail worstPos+0.0003 9.9995 # 6 m semi-span worstPos+0.0006 9.999 worstPos+0.006 9.99 worstPos+6-0.006 0.01 worstPos+6-0.0006 0.001 worstPos+6-0.0003 0.0005 worstPos+6 0.0 worstPos+6+.00001 0.0 worstPos+6+.00003 0.0 worstPos+6+.00004 0.0 worstPos+6+.00006 0.0 XtracStop 0.0 func intpl_r spv_trac # track gauge in mm -100.0 TrackGauge XtracStop TrackGauge func intpl_r fi_trac # cant in mm -100.0 0.0 -10.0 0.0 -9.0 0.0 -8.0 0.0 0.0 0.0 worstPos-6-.1 0.0 worstPos-6-.00006 0.0 # Several points in order to avoid ringing in the spline interpolation worstPos-6-.00004 0.0 worstPos-6-.00003 0.0 worstPos-6-.00001 0.0 worstPos-6 0.0 worstPos-6+0.0003 -0.001 worstPos-6+0.0006 -0.002 worstPos-6+0.006 -0.02 worstPos-0.006 -19.98 worstPos-0.0006 -19.998 worstPos-0.0003 -19.999 worstPos -20.0 # 20 dip on high rail worstPos+0.0003 -19.999 # 6 m semi-span worstPos+0.0006 -19.998 worstPos+0.006 -19.98 worstPos+6-0.006 -0.02 worstPos+6-0.0006 -0.002 worstPos+6-0.0003 -0.001 worstPos+6 0.0 worstPos+6+.00001 0.0 worstPos+6+.00003 0.0 worstPos+6+.00004 0.0 worstPos+6+.00006 0.0 XtracStop 0.0 # elseif_then_char_init ctrack_irreg .eq. "track_irr4" # }{ func const YMtrac 0.000650 # from mm to m, and factor 0.65 func const ZMtrac 0.000800 # from mm to m, and factor 0.80 func const GMtrac 0.001000 # from mm to m, and factor 0.65 func const CMtrac 0.000533 # from mm to rad, and factor 0.80 func const XtracStart= 0. func const XtracStop= 2003. func intpl_track_irr2 XtracStart XtracStop track/track_irr4.trax TrackGauge # elseif_then_char_init ctrack_irreg .eq. "track_V120a" # }{ func const YMtrac= 1e-3 # From mm to m; Scale factor 1.00; Lateral irregularities func const ZMtrac= 1e-3 # From mm to m; Scale factor 1.00; Vertical irregularities func const GMtrac= 1e-3 # From mm to m; Scale factor 1.00; Gauge irregularities func const CMtrac= 1e-3/(2*bo_) # From mm to rad; Scale factor 1.00; Cant irregularities func const XtracStart= 1400. func const XtracStop= 3100. func intpl_track_irr2 XtracStart XtracStop track/track_V120a.trax TrackGauge # elseif_then_char_init ctrack_irreg .eq. "track_V120b" # }{ func const YMtrac= 1e-3 # From mm to m; Scale factor 1.00; Lateral irregularities func const ZMtrac= 1e-3 # From mm to m; Scale factor 1.00; Vertical irregularities func const GMtrac= 1e-3 # From mm to m; Scale factor 1.00; Gauge irregularities func const CMtrac= 1e-3/(2*bo_) # From mm to rad; Scale factor 1.00; Cant irregularities func const XtracStart= 1050. func const XtracStop= 3000. func intpl_track_irr2 XtracStart XtracStop track/track_V120b.trax TrackGauge # elseif_then_char_init ctrack_irreg .eq. "track_V160a" # }{ func const YMtrac= 1e-3 # From mm to m; Scale factor 1.00; Lateral irregularities func const ZMtrac= 1e-3 # From mm to m; Scale factor 1.00; Vertical irregularities func const GMtrac= 1e-3 # From mm to m; Scale factor 1.00; Gauge irregularities func const CMtrac= 1e-3/(2*bo_) # From mm to rad; Scale factor 1.00; Cant irregularities func const XtracStart= 700. func const XtracStop= 4200. func intpl_track_irr2 XtracStart XtracStop track/track_V160a.trac TrackGauge # elseif_then_char_init ctrack_irreg .eq. "track_V200a" # }{ func const YMtrac= 1e-3 # From mm to m; Scale factor 1.00; Lateral irregularities func const ZMtrac= 1e-3 # From mm to m; Scale factor 1.00; Vertical irregularities func const GMtrac= 1e-3 # From mm to m; Scale factor 1.00; Gauge irregularities func const CMtrac= 1e-3/(2*bo_) # From mm to rad; Scale factor 1.00; Cant irregularities func const XtracStart= 0. func const XtracStop= 4997. func intpl_track_irr2 XtracStart XtracStop track/track_V200a.trac TrackGauge # else func print06_char_init " " func print06_char_init " ***ERROR*** In Input Reading" func print06_char_init " Unvalid value given for character variable ctrack_irreg" func stop endif # }} # s_var scalar_0 XtracStart # Save start coordinate as a scalar for post processing s_var scalar_0 XtracStop # Save stop coordinate as a scalar for post processing #[-]} - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

In the track irregularity files

trac, trax

and trax_wdesign

the errors are stored in [mm],

but all calculations in CALC are performed in SI-units,

therefore must the track irregularities be converted into [m].

The conversion into [m] is made by setting the constants, YMtrac,

ZMtrac and GMtrac equal to 0.001.

Variable CMtrac translates from [mm] to [rad],

therefore CMtrac is dependent on the gauge.

In order to automatically adjust for the current gauge used CMtrac has been defined as 1e-3/(2*bo_).

Track irregularity files written in trac-, trax- or trax_wdesign-format includes the measured gauge in absolute coordinates. In some cases the vehicle designer wish to change the average gauge of a track, in order to check the behavior of the vehicle in a tight or wide gauge.

For the above purposes the user has access to two key-variables gaugeAverage and gaugeDev_. The variables gaugeAverage and gaugeDev_ operates on column #4 in the track file in the following way:

tral$2.gauge= (column_4(axl_$2.pn) - gaugeAverage)*GMtrac + gaugeDev_ tral$2r.y= column_2(axl_$2.pn) + tral$2.gauge/2. tral$2l.y= column_2(axl_$2.pn) - tral$2.gauge/2.Where:

| axl_$2.pn | = | The longitudinal position of axle $2 (axl_$2.pn= lsa_$2.pn + axl_$2.x) |

| lsa_$2.pn | = | The longitudinal position of the local coordinate system for axle $2 |

| axl_$2.x | = | The longitudinal position of axle $2 relative to local coordinate system lsa_$2 |

| column_4(x) | = | The value of column #4 (gauge errors) interpolated at x in the track irregularity file |

| GMtrac | = | Unit translation and multiplying factor described under Track Irregularities above |

| column_2(x) | = | The value of column #2 (lateral errors) interpolated at x in the track irregularity file |

| tral$2r.y | = | lateral error on top of right rail under axle number $2 |

| tral$2l.y | = | lateral error on top of left rail under axle number $2 |

Example #1

Set the preferred average value of the gauge, by defining the variable track_width.

## ## Automatically modify the gauge of the track ## =========================================== func const track_width= 1435. func mean_r2_init Xavg gaugeAverage spv_trac Xtrac_start Xtrac_stop func print06_char_init ' ' func print06_init gaugeAverage func operp_init gaugeDev_= 0.001 * ( track_width - 1435. )

In the example above the average value of the gauge is changed to the value given in the variable track_width independently of what gauge the track data file has.

Example #2

Modify the average value of the gauge manually.

## ## Set the variables gaugeAverage and gaugeDev_ manually ## ====================================================== func const gaugeAverage= 1435. # Set the average gauge of the track # func const gaugeDev_= -0.008 # Make the track 8 mm tighter # func const gaugeDev_= -0.004 # Make the track 4 mm tighter func const gaugeDev_= 0.000 # Do not change the gauge of the track # func const gaugeDev_= 0.004 # Make the track 4 mm wider # func const gaugeDev_= 0.008 # Make the track 8 mm wider

The track gauge is modigied in two steps:

In the memory of program CALC the user has access to the following variables regarding the track irregularities:

| tral$2r.y | = | Lateral track irregularity on top of right rail under axle number $2 |

| tral$2l.y | = | Lateral track irregularity on top of left rail under axle number $2 |

| tral$2r.z | = | Vertical track irregularity on top of right rail under axle number $2 |

| tral$2l.z | = | Vertical track irregularity on top of left rail under axle number $2 |

Designed or nominal track geometry is deviation from tangent track that is made intentionally, e.g. curves and cant (superelevation). See further information under track/designed_track_geom.html

If track irregularities has been read with func intpl_track_irr3 this section must be omitted, otherwise the memory fields roTracDesign, fiTracDesign and zTracDesign will be defined twice and an error will occur.

Example of a S-shaped curve. The curve changes from a right handed curve direct to a left handed curve without an intermediate tangent track section.

### ### Designed(nominal) track geometry ### ========================================================== func const CurveRadius= 1e99 # Curve radius in [m] func const CurveCant= 0.000 # Cant of track in [m] #[-]{ # func intpl_r roTracDesign -100.+XtracStart 0. # Tangent track 40.+XtracStart 0. 160.+XtracStart 1/CurveRadius # Right handed circular curve 240.+XtracStart 1/CurveRadius 480.+XtracStart -1/CurveRadius # Left handed circular curve 560.+XtracStart -1/CurveRadius 680.+XtracStart 0. # Tangent track 1000.+XtracStart 0. func intpl_r fiTracDesign -100.+XtracStart 0. 40.+XtracStart 0. 160.+XtracStart CurveCant/(2*bo_) 240.+XtracStart CurveCant/(2*bo_) 480.+XtracStart -CurveCant/(2*bo_) 560.+XtracStart -CurveCant/(2*bo_) 680.+XtracStart 0. 1000.+XtracStart 0. func intpl_r zTracDesign -100.+XtracStart 0. 40.+XtracStart 0. 160.+XtracStart -abs(CurveCant)/2. 240.+XtracStart -abs(CurveCant)/2. 480.+XtracStart -abs(CurveCant)/2. 560.+XtracStart -abs(CurveCant)/2. 680.+XtracStart 0. 1000.+XtracStart 0. s_var scalar_0 CurveRadius s_var scalar_0 CurveCant func const CurveTCbeg1= 40+XtracStart # Beginning of transition curve func const CurveTCend1= 160+XtracStart # End of transition curve s_var scalar_0 CurveTCbeg1 # Store for evaluation s_var scalar_0 CurveTCend1 # of PCT #[-]} - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

In the example above the curve radius equals 1e99[m] which is practically equal to tangent track.

Variable Xtrac_start has previously been defined under section track irregularity.

This is a practical way of connecting the

designed track geometry and

track irregularities to each other.

The three memory fields: roTracDesign, fiTracDesign and zTracDesign defined above, will later be used in the lsys-command when creating the coordinate systems.

N.B. The description of the designed track must start on tangent track otherwise an error will occur.

### ### Wheel-rail contact model ### ------------------------------------------------------------- func char cwr_coupl= pe3 # Up to three simultaneous contact areas # func char cwr_coupl= pe4 # Up to 2x2 contact areas

In order to speed up simulation times so called wheel/rail geometry functions can be defined. These functions can be calculated with the KPF pre processor program. The definition of the wheel/rail geometry functions can be written in many different ways:

Same profiles on all vehiclesIf the train-set has the same wheel profiles on all vehicles, the definition of the wheel-rail geometry functions can be as the following:

## ## Define wheel-rail geometry functions ## ==================================== insert file $genkpf/ENS1002t32.5_uic60i40..kpfr in_substruct ENS1002t32.5_uic60i40 [ " " ] # All wheels in the vehicle

If the train-set has different wheel profiles on different vehicles, the definition of the wheel-rail geometry functions should be as the following:

## ## Define wheel-rail geometry functions ## ==================================== insert file $genkpf/ENS1002t32.5_uic60i40.kpfr insert file $genkpf/ENS1002t32.5_uic60i30.kpfr insert file $genkpf/ENS1002t32.5_uic60i20.kpfr # in_substruct ENS1002t32.5_uic60i40 [ 1 ] # Vehicle #1 in_substruct ENS1002t32.5_uic60i30 [ 2 ] # Vehicle #2 in_substruct ENS1002t32.5_uic60i20 [ 3 ] # Vehicle #3

If the train-set has different wheel-rail profiles on each wheel, the definition of the wheel-rail geometry functions should be as the following:

## ## Define wheel-rail geometry functions ## ==================================== insert file kpfr/wheel1_rail1.kpfr insert file kpfr/wheel2_rail1.kpfr insert file kpfr/wheel1_rail2.kpfr insert file kpfr/wheel2_rail2.kpfr # in_substruct kpf_wheel1_rail1 [ 111r ] # Axle 111 right side in_substruct kpf_wheel1_rail2 [ 111l ] # Axle 111 left side in_substruct kpf_wheel2_rail1 [ 112r ] # Axle 112 right side in_substruct kpf_wheel2_rail2 [ 112l ] # Axle 112 left side in_substruct kpf_wheel1_rail1 [ 121r ] # Axle 121 right side in_substruct kpf_wheel1_rail2 [ 121l ] # Axle 121 left side in_substruct kpf_wheel2_rail1 [ 122r ] # Axle 122 right side in_substruct kpf_wheel2_rail2 [ 122l ] # Axle 122 left side

If the user wishes to calculate the wheel/rail geometry functions by only give the wheel- and rail- profiles in the input data file. The following three lines can be used:

pre_process= 'create_kpfr kpff/Master.kpff kpf/S1002.wheel kpf/uic60i40.rail create_kpfr' insert file kpfr/create_kpfr.kpfr in_substruct create_kpfr [ " " ]

Script create_kpfr is located in directory $gensys/bin and is accessible via environment variable $PATH.

Argument no 1 is the input data file for program KPF.

Argument no 2 is the wheel profile.

Argument no 3 is the rail profile.

Argument no 4 an ident text string.

The in-line created kpfr-file is included with the insert-command and used with the in_substruct-command.

If not the wheel/rail geometries are constant along the track, the definition of the wheel-rail geometry functions can be written in the following way:

## ## Define a wheel-rail geometry functions which varies along the track ## ------------------------------------------------------------------- insert file $genkpf/S1002t32.5_bv50i30.kpfr insert file $genkpf/S1002t32.5_bv50i30_worn_r3.kpfr insert file $genkpf/S1002t32.5_bv50i30_worn_l3.kpfr in_substruct S1002t32.5_bv50i30 [ tangtrc ] in_substruct S1002t32.5_bv50i30_worn_r3 [ Rcurve ] in_substruct S1002t32.5_bv50i30_worn_l3 [ Lcurve ] # func kpf_variable_1 " " -100. tangtrc 40. tangtrc 45. Rcurve 355. Rcurve 360. tangtrc 365. Lcurve 675. Lcurve 680. tangtrc 1000. tangtrc

Above example shows a track consisting of 8 sections with different wheel/rail geometries.

| Region | Wheel/rail geometry function |

|---|---|

| -100 - 40. | tangtrc (tangent track) |

| 40. - 45. | Linear transition from tangtrc to Rcurve |

| 45. - 355 | Rcurve |

| 355 - 360 | Linear transition from Rcurve to tangtrc |

| ,,, etc. |

## ## Define wheel-rail geometry functions ## ========================================================== func char ckpfr= ENS1002t32.5_uic60i40 # if_then_char_init ckpfr .eq. "ckona_fl" func copy_init lambda0= 0.025 # Rail inclination 1/40 func copy_init lambda = 0.30 # Effective conicity s_var scalar_0 lambda func operp_init epsilon= 50.7 * ( lambda - lambda0 ) # Contact angle difference parameter insert file $genkpf/kpf_ckona_fl.kpfr in_substruct kpf_ckona [ " " lambda lambda0 epsilon ] # elseif_then_char_init ckpfr .eq. "rkona" insert file $genkpf/kpf_rkona.kpfr in_substruct kpf_rkona [ " " 0. ] # elseif_then_char_init ckpfr .eq. "ENS1002t32.5_uic60i40" insert file $genkpf/ENS1002t32.5_uic60i40.kpfr in_substruct ENS1002t32.5_uic60i40 [ " " ] # elseif_then_char_init ckpfr .eq. "ENS1002t32.5_uic60i30" insert file $genkpf/ENS1002t32.5_uic60i30.kpfr in_substruct ENS1002t32.5_uic60i30 [ " " ] # elseif_then_char_init ckpfr .eq. "ENS1002t32.5_uic60i20" insert file $genkpf/ENS1002t32.5_uic60i20.kpfr in_substruct ENS1002t32.5_uic60i20 [ " " ] # elseif_then_char_init ckpfr .eq. "SjNormalt33_uic60i40" insert file $genkpf/SjNormalt33_uic60i40.kpfr in_substruct SjNormalt33_uic60i40 [ " " ] # elseif_then_char_init ckpfr .eq. "SjNormalt33_uic60i20" insert file $genkpf/SjNormalt33_uic60i20.kpfr in_substruct SjNormalt33_uic60i20 [ " " ] # elseif_then_char_init ckpfr .eq. "Variable_W/R-geom" insert file $genkpf/S1002t32.5_bv50i30.kpfr insert file $genkpf/S1002t32.5_bv50i30_worn_r3.kpfr insert file $genkpf/S1002t32.5_bv50i30_worn_l3.kpfr in_substruct S1002t32.5_bv50i30 [ tangtrc ] in_substruct S1002t32.5_bv50i30_worn_r3 [ Rcurve ] in_substruct S1002t32.5_bv50i30_worn_l3 [ Lcurve ] func kpf_variable_1 " " -100. tangtrc 40. tangtrc 45. Rcurve 355. Rcurve 360. tangtrc 365. Lcurve 675. Lcurve 680. tangtrc 1000. tangtrc # else func print06_char_init " " func print06_char_init " ***ERROR*** In Input Reading" func print06_char_init " Unvalid value given for character variable ckpfr" func stop endif

Definition of variable mu_ to be used in command func wr_couple_pe3. (please see further down under section Substructures to VEHICLE(s)):

func const mu_ = 0.50 # Wheel/Rail Friction Coefficient

In program CALC the underscore character "_" has a very special meaning. It means that program CALC truncates the name of the variable until a defined variable can be found.

The reason for using this feature in this case is that it will be easy to define different coefficients of friction in different contact points on different wheels. Gensys will now read the wheel/rail friction coefficient according to:

| mu_ | = | The default value of the friction coefficient. Will be valid if no other variables with higher priority can be found. |

| mu_1 | = | The wheel/rail friction coefficient valid for the first vehicle in the train-set |

| mu_11 | = | The wheel/rail friction coefficient valid for the first bogie in the first vehicle |

| mu_111 | = | The wheel/rail friction coefficient valid for the first wheelset in the first bogie in the first vehicle |

| mu_111r | = | The wheel/rail friction coefficient valid for the right wheel in the first wheelset in the first bogie in the first vehicle |

| mu_111r1 | = | The wheel/rail friction coefficient valid for contact point cp1 on the right wheel in the first wheelset in the first bogie in the first vehicle |

Example: If the user in the input data file define the following three variables:

func const mu_111r1= 0.1 # Specific wheel/rail friction coefficient for cp1 on wheel 111r func const mu_1 = 0.2 # Specific wheel/rail friction coefficient for the first vehicle func const mu_ = 0.5 # Default wheel/rail friction coefficient

The contact point "cp1" on the right wheel on the leading axle will be given a coefficient of friction equal to 0.1. Other contact points on the first vehicle will be given a coefficient of friction equal to 0.2. All other contact points on the other vehicles will be given a coefficient of friction equal to 0.5.

Instead of defining a default friction coefficient for all contact patches on all wheels, create individual friction coefficients for all contact patches. To create individual friction coefficients the following substructure can be used:

## ## Friction coefficients individual for each contact patch on all wheels ## (will later be adjusted by substruct update_mu) ## ========================================================================================== func const muTread = 0.5 # Friction coeff from 30mm and up func const muFlange= 0.1 # Friction coeff up to 24mm. Between 24-30mm there is a linear transition substruct create_mu [ # $1= Wheelset number func const mu_$1l1= 0.5 func const mu_$1r1= 0.5 # Fric coeff func const mu_$1l2= 0.5 func const mu_$1r2= 0.5 func const mu_$1l3= 0.5 func const mu_$1r3= 0.5 func const mulf_$1l1= mu_$1l1/0.6 func const mulf_$1r1= mu_$1r1/0.6 # Creep relax func const mulf_$1l2= mu_$1l2/0.6 func const mulf_$1r2= mu_$1r2/0.6 func const mulf_$1l3= mu_$1l3/0.6 func const mulf_$1r3= mu_$1r3/0.6 s_var sngl mu_$1l1 s_var sngl mu_$1l2 s_var sngl mu_$1l3 s_var sngl mu_$1r3 s_var sngl mu_$1r2 s_var sngl mu_$1r1 ]

Before making calls to wheel/rail-couplings, call the above substruct for all wheelsets the model.

To update the friction coefficients depending on the positions of the contact patches. The following can be used:

## ## Update the friction coeff depending on the location of the contact point ## (From -.070 to +.032 the friction muTread applies. ## From +.033 to +.070 the friction muFlange applies. ## Between +.032 to +.033 is a linear transition area) ## ========================================================================================== substruct update_mu [ # $1= Wheel number no_warning func intpl_l mu_$1l1= cp1_$1l.posw -.070 muTread .032 muTread .033 muFlange .070 muFlang no_warning func intpl_l mu_$1l2= cp2_$1l.posw -.070 muTread .032 muTread .033 muFlange .070 muFlang no_warning func intpl_l mu_$1l3= cp3_$1l.posw -.070 muTread .032 muTread .033 muFlange .070 muFlang # no_warning func intpl_l mu_$1r3= cp3_$1r.posw -.070 muTread .032 muTread .033 muFlange .070 muFlang no_warning func intpl_l mu_$1r2= cp2_$1r.posw -.070 muTread .032 muTread .033 muFlange .070 muFlang no_warning func intpl_l mu_$1r1= cp1_$1r.posw -.070 muTread .032 muTread .033 muFlange .070 muFlang # no_warning func div mulf_$1l1= mu_$1l1 0.6 no_warning func div mulf_$1r1= mu_$1r1 0.6 no_warning func div mulf_$1l2= mu_$1l2 0.6 no_warning func div mulf_$1r2= mu_$1r2 0.6 no_warning func div mulf_$1l3= mu_$1l3 0.6 no_warning func div mulf_$1r3= mu_$1r3 0.6 ]

After the calls to wheel/rail-couplings has been made, the above substruct can be called for all wheelsets the model, to update the values of the friction coefficients.

Instead of defining a default friction coefficient for all contact patches on all wheels, create individual friction coefficients for all contact patches. To create individual friction coefficients the following substructure can be used:

##

## Friction coefficients individual for each contact patch on all wheels

## (will later be adjusted by substruct update_mu)

## ======================================================================================

func const mu_radius= 1/750 # Lubricate all curves tighter than 750 m

func const mu_def = 0.5 # Default friction coeff valid for curves bigger than 750 m

func const mu_or = 0.5 # Default friction coeff in curves; outer rail

func const mu_ir = 0.25 # Default friction coeff in curves; inner rail

func const mu_gcor= 0.1 # Friction coeff on gauge corner and below; outer rail

substruct create_mu [ # $1= Wheelset number

func const mu_$1l1= 0.5 func const mu_$1r1= 0.5 # Fric coeff

func const mu_$1l2= 0.5 func const mu_$1r2= 0.5

func const mu_$1l3= 0.5 func const mu_$1r3= 0.5

func const mulf_$1l1= mu_$1l1/0.6 func const mulf_$1r1= mu_$1r1/0.6 # Creep relax

func const mulf_$1l2= mu_$1l2/0.6 func const mulf_$1r2= mu_$1r2/0.6

func const mulf_$1l3= mu_$1l3/0.6 func const mulf_$1r3= mu_$1r3/0.6

#

s_var sngl mu_$1l1

s_var sngl mu_$1l2

s_var sngl mu_$1l3

s_var sngl mu_$1r3

s_var sngl mu_$1r2

s_var sngl mu_$1r1

]

Before making calls to wheel/rail-couplings, call the above substruct for all wheelsets the model.

To update the friction coefficients depending on the positions of the contact patches. The following can be used:

##

## Update the friction coeff depending on track curve radius and location of the contact point

## ===========================================================================================

substruct update_mu [ # $1= Wheel number

##

## First interpolate along the track depending on track curvature

## Lubricate tangent track with mu_def

## Lubricate tread with mu_ir for inner rail and mu_or for outer rail

## Lubricate gauge corner with mu_gcor for outer rail

## -------------------------------------------------------------------

func intpl_l mutl_$1= lsa_$1.b ## Tread left side as function of curve radius

-1. mu_ir -mu_radius-1e-6 mu_ir -mu_radius mu_def # Left handed curve lubricate left tread; inner rail

mu_radius mu_def mu_radius+1e-6 mu_or 1. mu_or # Right handed curve lubricate left tread; outer rail

func intpl_l mufl_$1= lsa_$1.b ## Flange left side as function of curve radius

-1. mu_ir -mu_radius-1e-6 mu_ir -mu_radius mu_def # Left handed curve lubricate left flange; inner rail

mu_radius mu_def mu_radius+1e-6 mu_gcor 1. mu_gcor # Right handed curve lubricate left flange; outer rail

#

func intpl_l mutr_$1= lsa_$1.b ## Tread right side as function of curve radius

-1. mu_or -mu_radius-1e-6 mu_or -mu_radius mu_def # Left handed curve lubricate right tread; outer rail

mu_radius mu_def mu_radius+1e-6 mu_ir 1. mu_ir # Right handed curve lubricate right tread; inner rail

func intpl_l mufr_$1= lsa_$1.b ## Flange right side as function of curve radius

-1. mu_gcor -mu_radius-1e-6 mu_gcor -mu_radius mu_def # Left handed curve lubricate right flange; outer rail

mu_radius mu_def mu_radius+1e-6 mu_ir 1. mu_ir # Right handed curve lubricate right flange; inner rail

##

## Second interpolate laterally depending on the lateral position of the contact points

## ------------------------------------------------------------------------------------

no_warning func intpl_l mu_$1l1= cp1_$1l.posr -.070 0.5 .026 0.5 .027 0.5 .070 0.5

no_warning func intpl_l mu_$1l2= cp2_$1l.posr -.070 0.5 .026 0.5 .027 0.5 .070 0.5

no_warning func intpl_l mu_$1l3= cp3_$1l.posr -.070 0.5 .026 0.5 .027 0.5 .070 0.5

no_warning func intpl_l mu_$1r3= cp3_$1r.posr -.070 0.5 .026 0.5 .027 0.5 .070 0.5

no_warning func intpl_l mu_$1r2= cp2_$1r.posr -.070 0.5 .026 0.5 .027 0.5 .070 0.5

no_warning func intpl_l mu_$1r1= cp1_$1r.posr -.070 0.5 .026 0.5 .027 0.5 .070 0.5

#

no_warning func copy mu_$1l1.y1= mutl_$1

no_warning func copy mu_$1l2.y1= mutl_$1 # Update the values in the above

no_warning func copy mu_$1l3.y1= mutl_$1 # interpolation

no_warning func copy mu_$1r3.y1= mutr_$1

no_warning func copy mu_$1r2.y1= mutr_$1

no_warning func copy mu_$1r1.y1= mutr_$1

#

no_warning func copy mu_$1l1.y2= mutl_$1

no_warning func copy mu_$1l2.y2= mutl_$1

no_warning func copy mu_$1l3.y2= mutl_$1

no_warning func copy mu_$1r3.y2= mutr_$1

no_warning func copy mu_$1r2.y2= mutr_$1

no_warning func copy mu_$1r1.y2= mutr_$1

#

no_warning func copy mu_$1l1.y3= mufl_$1

no_warning func copy mu_$1l2.y3= mufl_$1

no_warning func copy mu_$1l3.y3= mufl_$1

no_warning func copy mu_$1r3.y3= mufr_$1

no_warning func copy mu_$1r2.y3= mufr_$1

no_warning func copy mu_$1r1.y3= mufr_$1

#

no_warning func copy mu_$1l1.y4= mufl_$1

no_warning func copy mu_$1l2.y4= mufl_$1

no_warning func copy mu_$1l3.y4= mufl_$1

no_warning func copy mu_$1r3.y4= mufr_$1

no_warning func copy mu_$1r2.y4= mufr_$1

no_warning func copy mu_$1r1.y4= mufr_$1

#

no_warning func div mulf_$1l1= mu_$1l1 0.6 # Also update the creep relaxation factors

no_warning func div mulf_$1l2= mu_$1l2 0.6

no_warning func div mulf_$1l3= mu_$1l3 0.6

no_warning func div mulf_$1r3= mu_$1r3 0.6

no_warning func div mulf_$1r2= mu_$1r2 0.6

no_warning func div mulf_$1r1= mu_$1r1 0.6

]

After the calls to wheel/rail-couplings has been made, the above substruct can be called for all wheelsets the model, to update the values of the friction coefficients.

This block is mainly the same for all railway vehicle models.

N.B. This block do not create any input data for gensys.

These substructures will only be stored in temporary files,

waiting to be used in a in_substruct-command later in the file.

## ## Create wheelsets ## ==================================================================== substruct create_axl [ mass m_rigid_6 axl_$1 lsa_$1 0. 0. -ro_$1 ma_$1 ma_$1 ma_$1 Jfa_$1 Jka_$1 Jpa_$1 constr fix_free_1 axl_$1.k= 0. initval set_var axl_$1.vk= -Vo/ro_$1 ] ## ## Create track-pieces ## ==================================================================== substruct create_trc [ mass m_rigid_6f trc_$1 lsa_$1 0. 0. 0. 0. myt_$1 mzt_$1 Jft_$1 0. 0. constr fix_rigid_1 trc_$1 x 0. # constr fix_rigid_1 trc_$1 z 0. constr fix_rigid_1 trc_$1 k 0. constr fix_rigid_1 trc_$1 p 0. mass fixpoint_6 rail_$1r lsa_$1 0. bo_ 0. mass fixpoint_6 rail_$1l lsa_$1 0. -bo_ 0. ] ## ## Calculation of creep and creepforces between wheels and rails ## ================================================================ substruct wr_coupl_pe3 [ func wr_coupl_pe3 # $1 # Name/number of the wheelset lsa_$1 # Name of the linear local coordinate system # lat_trac vert_trac spv_trac fi_trac # Track irregularities memory fields YMtrac ZMtrac GMtrac CMtrac # Multiplication factors for track irregularities gaugeAverage # Average gauge of spv_trac gaugeDev_$1 # Modify average gauge for a different conicity 1 # Type of contact normal to the contact surface # axl_$1 # Body wheel right side axl_$1 # Body wheel left side trc_$1 # Body track right side trc_$1 # Body track left side # # # Right wheel: ro_$1r # Nominal radius 17e6 # kyrt_$1r # Lateral stiffness rail - track 230e6 # kzrt_$1r # Vertical stiffness rail - track -kmbaF0_$1+ma_$1/2*9.81 # kzrtF0_$1r # Vertical prestress force rail - track 10e3 # cyrt_$1r # Lateral damping rail - track 50e3 # czrt_$1r # Vertical damping rail - track bo_$1r # Lateral semi-distance to nominal running circle, right side # # # Left wheel: ro_$1l # Nominal radius 17e6 # kyrt_$1l # Lateral stiffness rail - track 230e6 # kzrt_$1l # Vertical stiffness rail - track -kmbaF0_$1+ma_$1/2*9.81 # kzrtF0_$1l # Vertical prestress force rail - track 10e3 # cyrt_$1l # Lateral damping rail - track 50e3 # czrt_$1l # Vertical damping rail - track -bo_$1l # Lateral semi-distance to nominal running circle, left side # cp1_$1r # Name of contact point #1 right side trc_$1 cp1_$1r.ksi cp1_$1r.bo 0. # Contact on track axl_$1 0. cp1_$1r.bo 0. # Contact on wheel/wheelset mu_$1r1 # Coefficient of friction 2.05e11 .3 # Modulus of elasticity and Poisson's ratio mu_$1r1/.6 mu_$1r1/.6 mu_$1r1/.6 # Creepage reduction due to contaminated rail surface 0. 2400e6 # Prestress force and stiffness normal to the surface # cp1_$1l trc_$1 cp1_$1l.ksi cp1_$1l.bo 0. # Contact on track axl_$1 0. cp1_$1l.bo 0. # Contact on wheel/wheelset mu_$1l1 # Coefficient of friction 2.05e11 .3 # Modulus of elasticity and Poisson's ratio mu_$1l1/.6 mu_$1l1/.6 mu_$1l1/.6 # Creepage reduction due to contaminated rail surface 0. 2400e6 # Prestress force and stiffness normal to the surface # # cp2_$1r trc_$1 cp2_$1r.ksi cp2_$1r.bo 0. # Contact on track axl_$1 0. cp2_$1r.bo 0. # Contact on wheel/wheelset mu_$1r2 # Coefficient of friction 2.05e11 .3 # Modulus of elasticity and Poisson's ratio mu_$1r2/.6 mu_$1r2/.6 mu_$1r2/.6 # Creepage reduction due to contaminated rail surface 0. 2400e6 # Prestress force and stiffness normal to the surface # cp2_$1l trc_$1 cp2_$1l.ksi cp2_$1l.bo 0. # Contact on track axl_$1 0. cp2_$1l.bo 0. # Contact on wheel/wheelset mu_$1l2 # Coefficient of friction 2.05e11 .3 # Modulus of elasticity and Poisson's ratio mu_$1l2/.6 mu_$1l2/.6 mu_$1l2/.6 # Creepage reduction due to contaminated rail surface 0. 2400e6 # Prestress force and stiffness normal to the surface # # cp3_$1r trc_$1 cp3_$1r.ksi cp3_$1r.bo 0. # Contact on track axl_$1 0. cp3_$1r.bo 0. # Contact on wheel/wheelset mu_$1r3 # Coefficient of friction 2.05e11 .3 # Modulus of elasticity and Poisson's ratio mu_$1r3/.6 mu_$1r3/.6 mu_$1r3/.6 # Creepage reduction due to contaminated rail surface 0. 2400e6 # Prestress force and stiffness normal to the surface # cp3_$1l trc_$1 cp3_$1l.ksi cp3_$1l.bo 0. # Contact on track axl_$1 0. cp3_$1l.bo 0. # Contact on wheel/wheelset mu_$1l3 # Coefficient of friction 2.05e11 .3 # Modulus of elasticity and Poisson's ratio mu_$1l3/.6 mu_$1l3/.6 mu_$1l3/.6 # Creepage reduction due to contaminated rail surface 0. 2400e6 # Prestress force and stiffness normal to the surface ] ## ## Animate track irregularities in GPLOT ## ====================================== substruct animateRails [ no_warning func copy rail_$1$2.y= tral$1$2.y no_warning func copy rail_$1$2.z= tral$1$2.z no_warning func copy rail_$1$2.k= tral$1$2.k no_warning func copy rail_$1$2.p= tral$1$2.p ] ## ## Coupling track - ground ## ========================================================== substruct create_trc_couplz [ coupl k3 kztg$2r trc_$2 0. bo_ 0.340 grd_$2 0. bo_ 0.340 kytg_$2r kytg_$2r kztg_$2r .25 .5 esys_$1 m coupl k3 kztg$2l trc_$2 0. -bo_ 0.340 grd_$2 0. -bo_ 0.340 kytg_$2l kytg_$2r kztg_$2r .25 .5 esys_$1 m # coupl kc cztg$2r trc_$2 0. bo_ 0.340 grd_$2 0. bo_ 0.590 kcztg_$2r cztg_$2r esys_$1 z coupl kc cztg$2l trc_$2 0. -bo_ 0.340 grd_$2 0. -bo_ 0.590 kcztg_$2l cztg_$2l esys_$1 z # coupl kc cytg$2 trc_$2 0. 0.2 0.172 grd_$2 0. -.2 0.172 kcytg_$2 cytg_$2 esys_$1 y ]For a sketch and more information about the track model, please look under Track Model.

## ## Wear- and RCF- indexes ## ================================================================ substruct wearRCF [ func fl_wear_w $1 mu_$11 mu_$12 mu_$13 s_var var_0 cpa_$1.Fnu s_var var_0 cp1_$1.Fnu s_var var_0 cp2_$1.Fnu s_var var_0 cp3_$1.Fnu s_var var_0 cpa_$1.FMnu s_var var_0 cp1_$1.FMnu s_var var_0 cp2_$1.FMnu s_var var_0 cp3_$1.FMnu func mul cp1_$1.nuxm= mu_/0.6 cp1_$1.nux # Reduced creepage according to mulf_ func mul cp2_$1.nuxm= mu_/0.6 cp2_$1.nux # I.e. dry friction only func mul cp3_$1.nuxm= mu_/0.6 cp3_$1.nux func mul cp1_$1.nuym= mu_/0.6 cp1_$1.nuy func mul cp2_$1.nuym= mu_/0.6 cp2_$1.nuy func mul cp3_$1.nuym= mu_/0.6 cp3_$1.nuy func cabs cp1_$1.num= cp1_$1.nuxm cp1_$1.nuym # Total creepage func cabs cp2_$1.num= cp2_$1.nuxm cp2_$1.nuym func cabs cp3_$1.num= cp3_$1.nuxm cp3_$1.nuym s_var sngl cp1_$1.num s_var sngl cp2_$1.num s_var sngl cp3_$1.num ## ## Yield Dang Residual Wear Contact Wear ## Name whe_ Stress Van Stress Limit ForceLlim Cp1 Cp2 Cp3 func rolling_fatigue_3 RCF_$1 $1 300e6 0.32 0. .0025 .0035 30e3 cp1_$1.num cp2_$1.num cp3_$1.num ## ## YieldStress= 300e6 after some hardening ## # RCF-surf according to the shake-down map: s_var sngl RCF_$1.FIs1 s_var sngl RCF_$1.FIs2 s_var sngl RCF_$1.FIs3 # RCF-surf attenuated with respect to wear: s_var sngl RCF_$1.FPs1 s_var sngl RCF_$1.FPs2 s_var sngl RCF_$1.FPs3 # func max RCF_$1.FIs= RCF_$1.FIs1 RCF_$1.FIs2 RCF_$1.FIs3 s_var sngl RCF_$1.FIs # Total RCF-surf according to shake-down map s_var sngl RCF_$1.FPs # Total RCF-surf attenuated with respect to wear s_var sngl RCF_$1.FPb # Total RCF-subsurf s_var sngl RCF_$1.FPd # Total RCF-deep subsurf ## Surface fatigue index Subsurface fatigue index Deep subsurface fatigue index s_var sngl RCF_$1.FPs s_var sngl RCF_$1.FPb s_var sngl RCF_$1.FPd s_var sngl RCF_$1.FPs1 s_var sngl RCF_$1.FIs1 s_var sngl RCF_$1.FPs2 s_var sngl RCF_$1.FIs2 s_var sngl RCF_$1.FPs3 s_var sngl RCF_$1.FIs3 func operp RCF_$1.FPbm= RCF_$1.FPb / 450e6 - 1 s_var sngl RCF_$1.FPbm ]

substruct saveCorrugation [ if_then_init .exist. cp1_$1l.nux func cabs cp1_$1l.anu= cp1_$1l.nux cp1_$1l.nuy func cabs cp1_$1r.anu= cp1_$1r.nux cp1_$1r.nuy s_var var_0 cp1_$1l.anu s_var var_0 cp1_$1r.anu endif if_then_init .exist. cp2_$1l.nux func cabs cp2_$1l.anu= cp2_$1l.nux cp2_$1l.nuy func cabs cp2_$1r.anu= cp2_$1r.nux cp2_$1r.nuy s_var var_0 cp2_$1l.anu s_var var_0 cp2_$1r.anu endif if_then_init .exist. cp3_$1l.nux func cabs cp3_$1l.anu= cp3_$1l.nux cp3_$1l.nuy func cabs cp3_$1r.anu= cp3_$1r.nux cp3_$1r.nuy s_var var_0 cp3_$1l.anu s_var var_0 cp3_$1r.anu endif ]

## ## Secant conicity ## ========================================================== substruct secant_conicity [ func operp cp_$1l.dr= ( cp1_$1l.Fn * cp1_$1l.dr + { cp2_$1l.Fn | 0. } * { cp2_$1l.dr | 0. } + { cp3_$1l.Fn | 0. } * { cp3_$1l.dr | 0. } ) / ( cp1_$1l.Fn + { cp2_$1l.Fn | 0. } + { cp3_$1l.Fn | 0. } ) func operp cp_$1r.dr= ( cp1_$1r.Fn * cp1_$1r.dr + { cp2_$1r.Fn | 0. } * { cp2_$1r.dr | 0. } + { cp3_$1r.Fn | 0. } * { cp3_$1r.dr | 0. } ) / ( cp1_$1r.Fn + { cp2_$1r.Fn | 0. } + { cp3_$1r.Fn | 0. } ) func operp tral$1.g= Track_Gauge*1e-3 + tral$1r.y - tral$1l.y + ral_$1r.y - ral_$1l.y func create_spline axl_$1.yoff= axlyoff_ tral$1.g func operp axl_$1.eta= ( cp_$1r.eta - cp_$1l.eta ) / 2. - axl_$1.yoff if_then axl_$1.eta .gt. 0.0005 func operp axl_$1.lam1= ( cp_$1r.dr - cp_$1l.dr ) / 2 / axl_$1.eta endif if_then axl_$1.eta .lt. -.0005 no_warning func operp axl_$1.lam1= ( cp_$1r.dr - cp_$1l.dr ) / 2 / axl_$1.eta endif func u_lim axl_$1.lam1= 1.2 func l_lim axl_$1.lam1= 0. func lpass2 axl_$1.lam2= axl_$1.lam1 3. 0.9239 func lpass2 axl_$1.lam = axl_$1.lam2 3. 0.3827 s_var sngl tral$1.g s_var sngl axl_$1.yoff s_var sngl axl_$1.eta s_var sngl axl_$1.lam1 s_var sngl axl_$1.lam ]

### ### Length to buffers ### ------------------------------------------------------------- func const buff.A_1= 6.5+1.5 # Coupler semi-distance

The speed of the vehicle can be defined in different ways:

Constant speed

Set speed according to a formula

Set speed according to cant deficiency

Read speed profile from an external file

Just create a variable named Vo. Gensys do always use SI-units in input data, why variable Vo shall be expressed in m/s. However the user can define another variable in order to express the speed in km/h or mph, for output in header lines etc.

func const vkmh= 160 # The initial speed of the vehicle in km/h func div Vo = vkmh 3.6 # Expressed in m/s s_var sngl vkmh # Save variable vkmh for postprocessing

or:

func const vmph= 100 # The initial speed of the vehicle in mph func div Vo = vkmh 2.236936 # Expressed in m/s s_var sngl vmph # Save variable speed for postprocessing

Variable Vo will later be used in the lsys-command when creating the coordinate systems.

N.B. The vehicle will only be given the speed Vo as an initial value.

This longitudinal speed may change during the simulation due to the slope of the track, energy dissipation in dampers and wheel/rail-contact,,, etc.

In long time-domain simulations, please regulate the longitudinal position of the vehicle in some way.

For more information see paragraph Regulate the longitudinal position of the vehicle under section VEHICLE(s).

In order to calculate max non-linear critical speed, variable vkmh can start at a very high value where the vehicle runs unstable. Then reduce the speed gradually until the vehicle becomes stable:

func const vkmhDeacc= 5 # Deacceleration when calculating critical speed func operp vkmh= 400 - vkmhDeacc * time # Vary vkmh linearily func div Vo = vkmh 3.6 # Expressed in m/s s_var sngl vkmh # Save variable vkmh for postprocessing

At the point where the oscillations of the vehicle stops is called the non-linear critical speed of the vehicle.

In order to also reduce the speed of the vehicle it is also necessary to apply braking forces on the vehicle(s). See further information about the braking forces at Excite the vehicle in order to calculate critical speed.

func const Y_cp= `.65 * sign(CurveRadius)` # lateral acc. in track plane func const vkmh= `3.6 * sqrt(CurveRadius * (Y_cp + CurveCant/(2*bo_)*9.81))` no_warning func min vkmh= vkmh 160 func div Vo = vkmh 3.6 s_var sngl vkmh

In this case vkmh will be controlled by the curve radius and cant of the curve. However its value will be maximized to 160 [km/h].

In the formula above the unit of Y_cp is [m/s].

Often the unit [mm] is used for defining cant deficiency.

The relation between cant deficiency expressed in [mm] and expressed in [m/s] is:

Y_cp= cant_deficiency_mm*1e-3/(2*bo_)*9.81

The following table shows the relation between Y_cp expessed in [mm] and [m/s] for

the most common cant deficiencies:

| cant deficiency [mm] |

Y_cp [m/s] |

|

|---|---|---|

| 100 | 0.6540 | ~0.65 |

| 150 | 0.9810 | ~1.00 |

| 180 | 1.1772 | ~1.18 |

| 245 | 1.6023 | ~1.60 |

When measuring track forces and ride comfort on an actual vehicle it can be difficult to keep a constant speed during the whole test. In order to compare measurements and simulations it is sometimes necessary to simulate with exactly the same speed profile as was used during the test. The following input data code can be used:

func intpl_r SpeedField insert free_form '(a,a)' track/Speed.txt # Vo speed in m/s lsys e_abs_bendrf esys_1 SpeedField `XtracStart - Buffer.A_1` roTracDesign fiTracDesign zTracDesign 4 4 4 4 4 4 func copy Vo= esys_1.vx func mul vkmh= esys_1.vx 3.6

The file track/Speed.txt comprises two columns.

The first column is the position along the track.

The second column is the speed of the vehicle.

Example: The first lines in file track/Speed.txt:

# # pos speed # [m] [m/s] # ----------- 0.00 34.30 0.17 34.30 0.34 34.30 0.51 34.30 0.69 34.30 0.86 34.30 1.03 34.30 1.20 34.30 1.37 34.30 1.54 34.30 1.72 34.31 1.89 34.30 2.06 34.30 2.23 34.30 . . .

N.B.

The input data code above only controls the motion of esys_1 and its linear local sub-coordinate systems.

In order to make the vehicle to follow the speed profile, the longitudinal position of the vehicle must be regulated.

See Regulate the longitudinal position of the vehicle under section VEHICLE(s).

### ### Euler coordinate systems #[-]{ ========================================================== func const Buffer.A_= 10.00 # Buffer semi-distance (longitudinal) lsys e_abs_bendrf esys_1 Vo `XtracStart - Buffer.A_1` roTracDesign fiTracDesign zTracDesign 4 4 4 4 4 4 # s_var sngl esys_1.b # Curvature s_var sngl esys_1.c # Cant s_var sngl esys_1.x # Positions of the Euler coordinate system s_var sngl esys_1.y # expressed in the fixed fsys-coordinate system s_var sngl esys_1.z # s_var sngl esys_1.vf # Roll speed for evaluation of PCT #[-]} - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Coordinate systems taking large rotations into consideration are Euler coordinate systems. These types of coordinate systems all begins with the letter e_ in GENSYS. Linear coordinate systems begins with the letter l_. Normally when creating a railway vehicle, only one esys is created per vehicle and that coordinate system is located approximately in the middle of the vehicle, and other linear lsys are related to this esys.

The speed of the Euler system is defined in argument Vo. However if the speed along the track varies according to a speed profile, a memory field can be inserted as an argument to lsys e_abs_bendrf.

Coordinate system lsys e_abs_bendrf is very similar to lsys e_abs_bend which defines an ideal transition curve of type clothoid. But coordinate system lsys e_abs_bendrf is more close to a transition curve we see in reality. Because in reality the transition curve have rounded corners in the beginning and in the end.

### ### Vehicle properties #[-]{ ========================================================== substruct vehProperties [ # $1 car_# ## ## Basic vehicle geometry ## ---------------------- func const acb_$1= 6.5 # bogie pivot semi-distance (longitudinal) func const aba_$1= 1.5 # wheelset semi-distance within a bogie (long.) ## ## Vehicle bodies ## -------------- ## Car-body (c) func const actaracg_$1= 0.0 # centre of gravity position, longitudinal func const hctaracg_$1= 2.0 # centre of gravity position, vertical func const mctara_$1= 52000 # mass func const Jfctara_$1= mctara_$1*(1.50^2+1.538^2)/3 # moment of inertia, roll func const Jkctara_$1= mctara_$1*(1.50^2+(acb_$1+aba_$1+.58)^2)/3 # moment of inertia, pitch func const Jpctara_$1= Jkctara_$1 # moment of inertia, yaw func const hfloor_$1= 1.3 # floor level ## ## Bogie frames (b) func const hbcg_$1= 0.7 # centre of gravity position, vertical func const mb_$1 = 10000 # mass func const Jfb_$1= 3000 # moment of inertia, roll func const Jkb_$1= 10000 # moment of inertia, pitch func const Jpb_$1= 15000 # moment of inertia, yaw ## ## Axles (a) func const ro_$1 = 0.50 # centre of gravity pos., vert. (wheel radius) func const ma_$1 = 2000 # mass func const Jfa_$1= 1200 # moment of inertia, roll func const Jka_$1= 250 # moment of inertia, pitch func const Jpa_$1= 1200 # moment of inertia, yaw ## ## Track pieces (t) func const myt_$1= 2e3*2.5*2.5*1.36 # Density 2e3 kg/m^2 func const mzt_$1= myt_$1 func const Jft_$1= mzt_$1*(2.5^2+2.5^2)/12 #### #### Secondary suspension: ##[-]{ ------------------------------------------------------------- ## ## Secondary suspension: Coil springs between car and bogie ## ------------------------------------------------------------ func const kzcb.B_$1= 1.0 # lateral semi distance [m] func const kzcb.H_$1= 1.0 # top of spring [m] func const kzcb.hs_$1= 0.32 # height of spring [m] coupl p_lin kxcb_$1= 0.0 600e3 # stiffness, longitudinal shear [N/m] coupl p_lin kycb_$1= 0.0 600e3 # stiffness, lateral shear [N/m] func const kzcbF0_$1= -mctara_$1*9.81/4 # preload force coupl p_lin kzcb_$1 = kzcbF0_$1 900e3 # stiffness, vertical compression [N/m] ## ## Secondary suspension: Anti-roll bars ## ----------------------------------------------------- func const kfcb.H_$1= 1.0 # Height above top of rail [m] coupl p_lin kfcb_$1 = 0. 2.5e6 # Roll stiffness [Nm/rad] ## ## Secondary suspension: Traction rods ## ----------------------------------------------------- func const ktr.Ac_$1= 7.5 # rod position in car-body, longitudinal func const ktr.Ab_$1= -.2 # rod position in bogie, longitudinal func const ktr.Bc_$1= 0.0 # rod position in car-body, lateral func const ktr.Bb_$1= 0.0 # rod position in bogie, lateral func const ktr.Hc_$1= 0.4 # rod position in car-body, vertical func const ktr.Hb_$1= 0.3 # rod position in bogie, vertical coupl p_lin ktr_$1= 0. 25e6 # stiffness coupl p_lin ctr_$1= 0. 100e3 # parallel viscous damping ## ## Secondary suspension: Lateral bumpstops ## ----------------------------------------------------- func const kycbs.H_$1= 1.0 # Height above top of rail [m] coupl p_nlin_s kycbs_$1= 0. 0.030, 0.0 # Break-point #1 [m],[N] 0.040, 15e3 # Break-point #2 [m],[N] 0.090, 2e6 # Break-point #3 [m],[N] ## ## Secondary suspension: Vertical bumpstops ## ----------------------------------------------------- func const kzcbs.A_$1= 0.0 # Longitudinal distance [m] func const kzcbs.B_$1= 1.0 # Lateral semi-distance [m] func const kzcbs.H_$1= 1.0 # Height above top of rail [m] coupl p_nlin_s kzcbs_$1= 0. 0.025, 0.0 # Break-point #1 [m],[N] 0.030, 15e3 # Break-point #2 [m],[N] 0.080, 2e6 # Break-point #3 [m],[N] ## ## Secondary suspension: Lateral viscous dampers ## -------------------------------------------------------- func const cycb.A_$1 = 0.34 # damper position, longitudinal func const cycb.Bc_$1= 0.9 # position in car-body, lateral func const cycb.Bb_$1= 0.4 # position in bogie, lateral func const cycb.Hc_$1= 0.7 # position in car-body, vertical func const cycb.Hb_$1= 0.6 # position in bogie, vertical coupl p_lin cycb_$1= 0.0 40e3 # damping coefficient ## ## Secondary suspension: Vertical viscous dampers ## -------------------------------------------------------- func const czcb.A_$1 = 0.34 # damper position, longitudinal func const czcb.B_$1 = 1.25 # damper position, lateral func const czcb.Hc_$1= 1.0 # position in car-body, vertical func const czcb.Hb_$1= 0.5 # position in bogie, vertical coupl p_lin czcb_$1= 0.0 40e3 # damping coefficient ## ## Secondary suspension: Yaw viscous dampers ## -------------------------------------------------------- func const cccb.Ac_$1= 7.3 # position in car-body, longitudinal func const cccb.Ab_$1= -0.4 # position in bogie, longitudinal func const cccb.Bc_$1= 1.3 # position in car-body, lateral func const cccb.Bb_$1= 1.3 # position in bogie, lateral func const cccb.Hc_$1= 0.7 # position in car-body, vertical func const cccb.Hb_$1= 0.6 # position in bogie, vertical coupl p_lin kccb_$1= 0. 25e6 # series stiffness coupl p_nlin cccb_$1= 0. -1.032 -26e3 # Blow-off compression -0.032 -16e3 # Damping coeff. compression 0. 0. 0.032 16e3 # Damping coeff. expansion 1.032 26e3 # Blow-off expansion ##[-]} - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - #### #### Primary suspension: ##[-]{ ---------------------------------------------------------------------------- ## ## Primary suspension: springs ## ---------------------------------------------------------------------------- func const kmba.B_$1= 1.0 # spring position, lateral # func const kmbaF0_$1= (2*kzcbF0_$1-mb_$1*9.81)/4 coupl p_lin36 kmba_$1= 0. 0. kmbaF0_$1 0. 0. 0. 20e6 0. 0. 0. 0. 0. 0. 20e6 0. 0. 0. 0. 0. 0. 1200e3 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. # coupl p_lin36 cmba_$1= 0. 0. 0. 0. 0. 0. 20e3 0. 0. 0. 0. 0. 0. 20e3 0. 0. 0. 0. 0. 0. 5e3 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. ## ## Primary suspension: Lateral bumpstops ## ---------------------------------------------------------------------------- func const kybas.H_$1= 0.4 # Height above top of rail [m] coupl p_nlin_s kybas_$1= 0. # symmetric non-linear stiffness 0.025 0.0 # break-point #1 0.050 1e6 # break-point #2 ## ## Primary suspension: Vertical bumpstops ## ---------------------------------------------------------------------------- func const kzbas.A_$1= 0.0 # Longitudinal distance [m] func const kzbas.B_$1= 1.1 # Lateral semi-distance [m] func const kzbas.H_$1= 0.4 # Height above top of rail [m] coupl p_nlin_s kzbas_$1= 0. # symmetric non-linear stiffness 0.025 0.0 # break-point #1 0.050 1e6 # break-point #2 ## ## Primary suspension: Vertical viscous damper ## ---------------------------------------------------------------------------- func const czba.A_$1 = 0.0 # damper position, longitudinal func const czba.Bb_$1= 1.1 # damper position, lateral in bogie func const czba.Ba_$1= 1.1 # damper position, lateral in axle func const czba.Hb_$1= 1.0 # damper position, vertical in bogie func const czba.Ha_$1= ro_$1 # damper position, vertical in axle coupl p_lin czba_$1= 0. 60e3 # viscous damping ## ## Coupling track - ground ## ========================================================== coupl p_lin kytg_$1 = 0. 40e6 coupl p_lin cytg_$1 = 0. 2*.55*sqrt(kytg_$1.v1*myt_$1) coupl p_lin kcytg_$1= 0. 2*pi*072.*cytg_$1.v1 coupl p_lin kztg_$1 = kmbaF0_$1-(ma_$1+mzt_$1)/2*9.81 220e6 # Stiffness under ballast coupl p_lin cztg_$1 = 0. 2*0.36*sqrt(kztg_$1.v1*mzt_$1/2) # Damping in ballast coupl p_lin kcztg_$1= 0. 2*pi*91*cztg_$1.v1 ##[-]} - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ] #[-]} - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - in_substruct vehProperties [ " " ] # $1 car_#

In above example you can see that subtructure vehProperties is called with the argument " ". This means that argument $1 will be replaced with the "space" character, i.e. nothing.

Therefore all property names will end with an underscore character "_". Indicating that these values are the default values of all properties or a variables.

In program CALC the underscore character "_" has a very special meaning. For example, if a property or a variable in gensys is called czba_111r it means that the damping coefficient for the vertical damper located on the right side of the first axle in the first bogie in the first vehicle shall have this value. If property or variable czba_111r not can be found then will gensys continue and search for the property or variable czba_111. If this property or variable not can be found either, program CALC will continue and search for the property or variable czba_11,,, etc. until the name czba_ has been reached. If property or variable czba_ not can be found program CALC will write an error message and stop further execution.

By using this name convention it is easy to model asymmetric vehicle in gensys. E.g. if input data looks like this:

coupl p_lin czba_ = 0. 60e3 coupl p_lin czba_111r= 0. 0. coupl p_lin czba_121 = 0. 30e3

This will model a vehicle where default value of the vertical primary dampers is 60e3. But the damper on the right side of axle 111 is broken, and both dampers on axle 121 have only 50% left of their capacity.

### ### Load properties #[-]{ ------------------------------------------------------------- substruct loadProperties [ # $1 car_#, $2 Weight, $3 C.g. long pos, $4 C.g. height, $5 Length, $6 Width, $7 Height func const mcload_$1 = $2 # Load weight func const acloadcg_$1= $3 # c.g. longitudinal func const hcloadcg_$1= $4 # c.g. vertical func const Jfcload_$1= `mcload_$1*($7^2+$6^2)/12` func const Jkcload_$1= `mcload_$1*($5^2+$7^2)/12` func const Jpcload_$1= `mcload_$1*($6^2+$5^2)/12` # func const mc_$1 = `mctara_$1 + mcload_$1` # Total weight func const accg_$1=`(actaracg_$1*mctara_$1 + acloadcg_$1*mcload_$1) / mc_$1` # Centre of gravity position, longitudinal func const hccg_$1=`(hctaracg_$1*mctara_$1 + hcloadcg_$1*mcload_$1) / mc_$1` # Centre of gravity position, vertical # func const Jfc_$1= `Jfcload_$1 + mcload_$1* (hcloadcg_$1-hccg_$1)^2` func const Jkc_$1= `Jkcload_$1 + mcload_$1*((acloadcg_$1-accg_$1)^2+(hcloadcg_$1-hccg_$1)^2)` func const Jpc_$1= `Jpcload_$1 + mcload_$1* (acloadcg_$1-accg_$1)^2` # no_warning func const Jfc_$1= `Jfctara_$1 + mctara_$1* (hctaracg_$1-hccg_$1)^2 + Jfc_$1` no_warning func const Jkc_$1= `Jkctara_$1 + mctara_$1*((actaracg_$1-accg_$1)^2+(hctaracg_$1-hccg_$1)^2) + Jkc_$1` no_warning func const Jpc_$1= `Jpctara_$1 + mctara_$1* (actaracg_$1-accg_$1)^2 + Jpc_$1` ] #[-]} - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - in_substruct loadProperties [ "1" 0e3 0. 1.650 14.000 2.400 1.300 ] # in_substruct loadProperties [ "2" 0e3 0. 1.650 14.000 2.400 1.300 ]

Cargo and passengers can be rigidly attached to the car-body as in substructure loadProperties above. This substructure is called for each vehicle in the train-set, allowing to have different loads on different vehicles.

If the user wants to make a better model, the load can be modeled in a separate mass. and connected to the car-body with springs and dampers.

The whole vehicle is modeled in a big substructure named vehicle. By writing the input data file in this way it is easy to create many vehicles in the train-set.

### ### VEHICLE(s) #[-]{ ========================================================== substruct vehicle [ # $1 car_#

A sketch of the vehicle

The sketch is not necessary but it helps new readers to understand the model.

## ## A sketch of the vehicle ## =========================================== ! ! ! _________________________________________________|_________________________________________________ ! / | \ ! / | \ ! / | \ ! / | \ ! / | \ ! / | \ ! / | mc_, Jfc_, Jkc_, Jpc_ \ ! \ -O-------------------------------------------------------/--------- ! \______________________________________________________|______________________________________________________/ ^ ! ____________|_____________ | ____________|_____________ | ! | | | | | |mb_,Jfb_,Jkb_,Jpb_ |hccg_ ! | | | | | -O---------------------- | ! |____________|_____________| | |____________|_____________| ^ | ! ___ | ___ | ___ | ___ | | ! / \ | / \ | / \ | / \ |hbcg_ | ! | + | | | + | | | + | | | + | | | ! _r.l.______\___/_____|______\___/_________________________|_________________________\___/_____|______\_|_/______|________|____ ! | | | | ! lsa_$122 lsb_$12 lsa_$121 lsc_$1 lsa_$112 lsb_$11 lsa_$111 ! | | | | ! | | acb_ | aba_ | ! | |---------------------------------->|------->| ! | ! esys_$1 !

Linear local coordinate systems

It is a good practice to have separate coordinate systems for all masses that have different longitudinal positions along the track,

because then will all displacements be expressed relative to the track where the mass is located.

However do not create unnecessarily many coordinate system, because that will lead to longer execution times.

## ## Local linear coordinate systems ## =============================== ## ## lsys l_local l_name esys a b h ## ----------------------------------------------------- lsys l_local lsc_$1 esys_$1 0.0 0.0 0.0 lsys l_local lsb_$11 lsc_$1 acb_$1 0.0 0.0 lsys l_local lsb_$12 lsc_$1 -acb_$1 0.0 0.0 lsys l_local lsa_$111 lsb_$11 aba_$11 0.0 0.0 lsys l_local lsa_$112 lsb_$11 -aba_$11 0.0 0.0 lsys l_local lsa_$121 lsb_$12 aba_$12 0.0 0.0 lsys l_local lsa_$122 lsb_$12 -aba_$12 0.0 0.0 # s_var sngl lsc_$1.vf # Roll speed for calculation of PCT

Vehicle and track masses

All properties has previously been defined under section Vehicle properties.

All substructures has previously been defined under section Substructures to VEHICLE(s).

Ground point grd_$1 is used for connecting a soft longitudinal spring to the car-body of the vehicle,

in order to keep up the speed during long simulations.

For more information see paragraph Regulate the longitudinal position of the vehicle under section VEHICLE(s).

Ground points grd_$111, grd_$112, grd_$121 and grd_$122 are used for connecting the track model to the fixed ground.

#### #### Vehicle and track masses ##[-]{ ================================================================ ## ## mass m_rigid_6 m_name lsys acg bcg hcg m m m Jf Jk Jp ## ------------------------------------------------------------------------------------------------ mass m_rigid_6 car_$1 lsc_$1 accg_$1 0.0 -hccg_$1 mc_$1 mc_$1 mc_$1 Jfc_$1 Jkc_$1 Jpc_$1 # car-body mass m_rigid_6 bog_$11 lsb_$11 0.0 0.0 -hbcg_$11 mb_$11 mb_$11 mb_$11 Jfb_$11 Jkb_$11 Jpb_$11 # bogies mass m_rigid_6 bog_$12 lsb_$12 0.0 0.0 -hbcg_$12 mb_$12 mb_$12 mb_$12 Jfb_$12 Jkb_$12 Jpb_$12 ## ## Create wheelsets ## ==================================================================== in_substruct create_axl [ $111 ] in_substruct create_axl [ $112 ] in_substruct create_axl [ $121 ] in_substruct create_axl [ $122 ] ## ## Create track-pieces ## ==================================================================== in_substruct create_trc [ $111 ] in_substruct create_trc [ $112 ] in_substruct create_trc [ $121 ] in_substruct create_trc [ $122 ] # mass fixpoint_6 grd_$1 lsc_$1 0.0 0.0 0.0 # ground points mass fixpoint_6 grd_$111 lsa_$111 0.0 0.0 0.0 mass fixpoint_6 grd_$112 lsa_$112 0.0 0.0 0.0 mass fixpoint_6 grd_$121 lsa_$121 0.0 0.0 0.0 mass fixpoint_6 grd_$122 lsa_$122 0.0 0.0 0.0 ##[-]} - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Regulate the longitudinal position of the vehicle

The longitudinal position of the vehicle must be regulated to avoid too big longitudinal difference between the masses and their coordinate systems.

In reality the vehicles rolls freely along the track, there is no spring or damper that controls their longitudinal positions.

However when simulating through curves the wheelsets must not deviate too much from their coordinate systems,

because the deviation can cause a angle of attack in the contact points.

If the longitudinal difference between a mass and its coordinate systems is more than 0.1[m] a warning message will be written on error output,

and the user will be recommended to regulate the position of the vehicle better.

Reasons that causes error in longitudinal position of the vehicle:

The most simple speed regulator is a linear spring and damper connected between car_$1 and the fixed point grd_$1:

#### #### Regulate the longitudinal position of the vehicle #### (In order to keep the speed up during long simulations) ##[-]{ ================================================================ ## ## Longitudinal stiffness connecting the car-body to the lsc_$1 coordinate system ## ============================================================================= func const mvhe_$1= mc_$1+mb_$11+mb_$12+ma_$111+Jka_$111/ro_$111^2+ma_$112+Jka_$112/ro_$112^2+ma_$121+Jka_$121/ro_$121^2+ma_$122+Jka_$122/ro_$122^2 coupl k kxcg1 car_$1 0 0 -hccg_$1*.6 grd_$1 0 0 -hccg_$1*.6 (2*pi*.25)^2*mvhe_$1 esys_$1 x # fo= 0.25[Hz] coupl c cxcg1 car_$1 0 0 -hccg_$1*.6 grd_$1 0 0 -hccg_$1*.6 4*pi*.7*.25*mvhe_$1 esys_$1 x # zeta=0.7 ##[-]} - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

A better speed regulator could consist of a PID-regulator. This example shows a PID-regulator that generates a pitch moment on the wheel-sets:

#### #### Regulate the longitudinal position of the vehicle #### (In order to keep the speed up during long simulations) ##[-]{ ================================================================ ## ## Apply pitch moment on the wheelsets ## ========================================================== func const fxcg= 0.25 func const mvhe_$1= mc_$1+mb_$11+mb_$12+ma_$111+Jka_$111/ro_$111^2+ma_$112+Jka_$112/ro_$112^2+ma_$121+Jka_$121/ro_$121^2+ma_$122+Jka_$122/ro_$122^2 func const Kreg_$1= (2*pi*fxcg)^2*mvhe_$1*ro_$1/4 func const Creg_$1= 4*pi*.70*fxcg*mvhe_$1*ro_$1/4 func operp car_.x = ( car_$1.x * mc_$1 + bog_$11.x * mb_$11 + bog_$12.x * mb_$12 + axl_$111.x * ma_$111 + axl_$112.x * ma_$112 + axl_$121.x * ma_$121 + axl_$122.x * ma_$122 ) / mvhe_$1 func operp car_.vx= ( car_$1.vx * mc_$1 + bog_$11.vx * mb_$11 + bog_$12.vx * mb_$12 + axl_$111.vx * ma_$111 + axl_$112.vx * ma_$112 + axl_$121.vx * ma_$121 + axl_$122.vx * ma_$122 ) / mvhe_$1 # func mul MtractionK_$1= Kreg_$1 car_.x func mul MtractionC_$1= Creg_$1 car_.vx func add Mtraction_$1= MtractionK_$1 MtractionC_$1 func lpass2_0 MtractionF1_$1= Mtraction_$1 5. .9239 # Second order low pass filter, start value equal to 0(zero) func lpass2_0 MtractionF2_$1= MtractionF1_$1 5. .3827 # Second order low pass filter, start value equal to 0(zero) # func incr axl_$111.Mk= MtractionF2_$1 func incr axl_$112.Mk= MtractionF2_$1 func incr axl_$121.Mk= MtractionF2_$1 func incr axl_$122.Mk= MtractionF2_$1 ##[-]} - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

An even better model can be created if the regulating force is created by applying a contact force between the wheelset and the bogie frame on the cog-wheels in the gearbox.

N.B. If a speed profile has been given under Speed above, accelerations and retardations can be very high. This can lead to very high pitch velocities of the wheelsets. Please make sure that the friction between wheel and rail is sufficient.

Acceleration variables for Ride Index calculations

The acceleration signals are used for Ride Comfort evaluations.

The evaluation takes place in postprocessor MPLOT.

The output variables from the commands are stored on the id-file with the substructure $gensys/calc/insert_files/save_car1.ins

mentioned under Save-files above.

## ## Acceleration response points on car-body floor ## ============================================== func accp_bodyf0 car_$1b1 car_$1 acb_$1 0.0 -hfloor_$1 func accp_bodyf0 car_$1_m car_$1 0.0 0.0 -hfloor_$1 func accp_bodyf0 car_$1b2 car_$1 -acb_$1 0.0 -hfloor_$1

####

#### Passengers

##[-]{ ==============================================

!

! _______________

! | |

! | |

! | spass | # Sprung passenger mass

! | | # 90 % of total passenger weight

! | |

! | |

! |_______________|

! | |

! / | | | # Stiffness and damping in passenger

! kpass \ |_|_| cpass # Eigenfrequency 5 [Hz]

! / |___| # Relative damping 50 %

! \ |

! __|_________|__

! | | # Unsprung passenger mass

! | upass | # 10 % of total passenger weight

! |_______________|

! | |

! / | | |

! kseat \ |_|_| cseat

! / |___|

! \ |

! __|_________|__

!

! car-body

!

!

coupl p_lin36 kpass_= 0. 0. -9.81*72 0. 0. 0.

(2*pi*5)^2*80 0. 0. 0. 0. 0.

0. (2*pi*1)^2*80 0. 0. 0. 0.

0. 0. (2*pi*5)^2*80 0. 0. 0.

0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0.

#

coupl p_lin36 cpass_= 0. 0. 0. 0. 0. 0.

2*0.5*(2*pi*5)*80 0. 0. 0. 0. 0.

0. 2*0.5*(2*pi*1)*80 0. 0. 0. 0.